Verification and Validation are terms commonly used during the development phases in various engineering fields, such as systems engineering, software engineering, chemical engineering, safety engineering and civil engineering.

Verification answers the question: “Did we build the system right?”

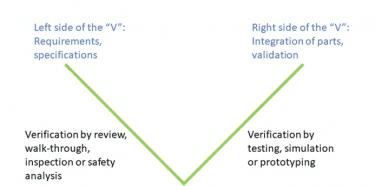

As per ISO 26262, verification is defined as the determination of completeness and correct specification or implementation of requirements from a phase or a sub phase. It is performed throughout the safety lifecycle, by every party involved in the process, for each of the major work products created. Functional safety verification is commonly performed on, but not limited to, safety requirements of various levels (functional, technical, software, hardware) after integration at multiple stages of the development process. Hence, verification is performed on the right-hand side as well as the left-hand side of the “V” development lifecycle as shown below.

Typical functional safety verification activities involve:

- Verification review, walk-through, and inspection

- Safety Analysis (Safety FMEA, Safety FTA, HAZOP, ETA, etc.)

- Simulation

- Prototyping

- Verification testing

- Integration and testing

- Hardware-software integration

- System integration and testing

- Vehicle integration and testing

Validation answers the question: “Did we build the right system?”

Safety validation is defined as the assurance, based on examination and tests, that the safety goals are sufficient and have been achieved. It is performed at the final stage of the development process before the functional safety assessment. As suggested by the standard, the functional safety validation is to ensure that the safety goal and the highest-level safety requirement has been met and is correct and is typically performed by the OEM at the vehicle level. Hence, validation is performed only on the right-hand side of the “V” development cycle after the completion of the integration and verification.

Typical functional safety validation activities involve:

- Validation testing (can be the tests from verification testing at vehicle level in specific cases)

- Safety Analysis (Safety FMEA, Safety FTA, ETA, etc.)

- Long-term tests

- User tests under real life conditions

- Reviews